Thanks to its eight measuring channels, it is possible to distinguish particle sizes of between 4 μm and 70 μm.

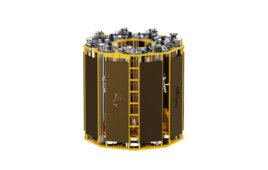

The LPM II Particle Monitor from STAUFF uses newly developed high-performance LEDs, which provide a precise image of the degree of contamination in the hydraulic system. Thanks to its eight measuring channels, it is possible to distinguish particle sizes of between 4 μm and 70 μm. This lets users assess the contamination even at higher contamination classes. The LPM II is permanently installed for continuous monitoring of the hydraulic system. As a result, the LPM II lets users quickly respond to increasing contamination, thus protecting the system from expensive failures and machine downtimes.

It comes in two versions: LPM II-D with display and keypad; and LPM II-O without display and keypad. (Either unit is available with a built-in moisture sensor.)

Because of its durable and compact structure, the LPM II is not sensitive to jolts, shocks, dust and moisture (IP 65 International Protection Rating) and can be used with almost any common hydraulic fluid. The device shows the measured data on the display as a contamination class according to ISO 4406:1999, NAS 1638, AS 4059E and ISO 11218 or as a particle count per size.

If the hydraulic system is not easy to access, a separate LPM II-REMOTE can be installed in a conveniently location. Integrated Modbus and CAN Bus interfaces can be used to connect the device to existing machine controls and data acquisition systems.

Stauff USA

www.stauffusa.com

Filed Under: Hydraulics, News