MagnaShear motor brakes are totally enclosed from outside contaminants, with seal integrity for harsh and washdown environments. A modular design and assembly allows for ease of servicing and maintenance.

MagnaShear motor brakes use oil-shear technology for longer service life even in demanding applications such as pitch and yaw drives and generator-holding brakes in smaller wind turbines. The proven technology transmits torque between lubricated surfaces – thereby eliminating wear on friction surfaces. A patented fluid recirculation system dissipates heat – a common problem in dry-braking systems. Eliminating wear significantly increases service life and nearly eliminates adjustment.

Oil shear also provides a smooth “cushioned” stop which reduces shock to the drive system, further extending service life of downstream components. These totally enclosed brakes are impervious to moisture, dirt, and dust common in outdoor applications such as wind farms. Seal integrity makes them ideal for harsh environments and washdown applications.

Unlike dry brakes, oil-shear design uses a layer of automatic transmission fluid between the brake disc and drive plate. As the fluid is compressed, fluid molecules shear – thus imparting torque to the other side. This torque transmission causes the stationary surface to turn, bringing it up to the same relative speed as the moving surface. Because most work is done by the fluid particles in shear, wear is almost eliminated, which also eliminates need the adjustments common to dry braking systems.

MagnaShear brakes provide significantly longer service life, characterized by near maintenance-free operations. These motor brakes are available to accommodate a wide range of applications. Spring-set torque ratings are from 3 to 1,250 ft-lb. Motor brakes can be sized to the correct torque independent of the motor frame size or horsepower.

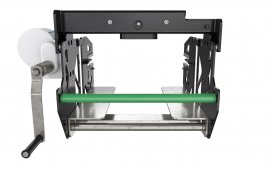

A “quick mount” features makes for quick and easy mounting to drive motors in NEMA frame sizes 56 to 449. They are shipped ready to install, without assembly or adjustments. They are also available pre-mounted on a motor for severe duty applications. MagnaShear motor brakes can be furnished to fit a NEMA or IEC frame motor, as a complete motor and brake assembly, or to mount on a machine frame or other special mounting configuration.

Force Control Industries

www.forcecontrol.com

Filed Under: Pitch & yaw