At a recent O&M conference, the topic of technician retention came up. Among the several suggestions was making their jobs easier with service lifts and lighter tools. This discussion deals with such tools.

A lighter hydraulic pump

The right tools let wind crews uphold safety, improve efficiency, and minimize their environmental impact. These goals ensure a crew’s wellbeing and mitigate the ever-present risks of downtime and slow production.

Recent wind-power-bolting tools have brought crews faster, safer production. One such advanced tool is the Stratus Electric Tensioner Pump. “It’s lightweight for easy maneuvering and it operates with a simple two-button pendant remote complete with a quick release clasp and an emergency safety button,” says Aztec Bolting Services President Larry Garza. “Fast pressure-up and retract features require less time bolting of foundations, blades, gear boxes, and more.”

Another new tool, Enerpac’s Electric Torque Wrench or ETW Series, will be released later this year. It offers wind-turbine crews a small footprint, low vibration and high speed operation, fastening verification, and more, making it compatible for wind tower construction. “These next-generation products give wind crews innovative technology for how they perform their critical work for bolt integrity,” adds Garza. “We use the tools, and train and certify others to use them.”

A rugged battery-powered wrench

For quite some time, requests have been made for a battery-powered-bolting system for wind-turbine maintenance. A few solutions were available, but the general consensus in the field was that none could withstand the rigorous usage required by wind technicians. Common issues included overheating, bending, and battery longevity.

“In response to the demand, engineers at my company have spent nearly five years developing a battery powered torque gun from the ground up,” says HYTORC Chief Operating Officer Jason Junkers. “The entire tool was custom designed to meet the industry’s needs.” Working with a select group of users in the wind-power industry, prototypes of the tools were tested in the field until a final model was ready for production.

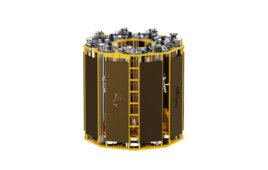

The Lithium Series tools are the first to use a 36-volt lithium-ion battery pack for industry-leading battery life. Available in multiple sizes, with torque output going as high as 3,000 ft-lb, these tools easily handle torque checks and other maintenance tasks on most wind turbines. Technicians will appreciate the compact and lightweight design, instead of having to lug a 75-lb hydraulic pump up a ladder to the nacelle. Custom hardware and software ensures maximum torque until the end of the battery’s life and it allows torque and angle-bolting methods.

An accurate electric wrench

As the wind power industry matures, OEM’s, owner and operators, and construction companies are all looking to more accurately collect and maintain their installation and service records. “Collecting and maintaining proper records gives companies documentation of the procedures they offer to their customers and lets them go back and review if any questions arise down the road,” says AIMCO’s Energy Services Manager Paul Bundy.

To accurately collect torque data, it is important to first understand the different technologies available. There are two basic types of products on the market: open loop and closed loop. “Open-loop technologies, such as hydraulic and electric-current-controlled tools, calculate a psi value at the pump, or a voltage-current at the controller, and assume a torque result at the socket end of the tools. Closed-loop technologies, on the other hand, such as our company’s AcraDyne HT series, use a built-in transducer at the working end of the tool to accurately deliver and collect the torque applied to the fastener, not at the pump or controller end,” adds Bundy. Those responsible for structural maintenance can be assured the job is done correctly, he says. And once a project completes, all data collected can be stored in an Excel spread sheet for future review.

Filed Under: News