Greensolver provides a new, cost-effective way to rapidly assess and monitor the condition of wind turbines.

Greensolver, an independent wind and solar farm asset manager, recently launched its wind turbine blade inspection service, which provides developers, investors, and utilities a cost-effective way to rapidly assess and monitor the condition of their equipment.

The launch of the service marks a milestone in the evolution of the operations and maintenance market and, for the first time, gives owners and operators a credible means through which they can assess and manage the long-term condition of wind turbine blades.

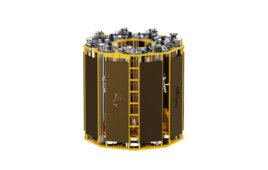

The service, based on a Cornis camera, enables owners and operators to assess six to seven onshore turbines (or a minimum of three offshore turbines) every day. This significantly increases the current speed and accuracy at which most traditional blade inspections are undertaken, providing a more comprehensive overview of short and long-term portfolio performance.

As part of the collaborative working agreement, Greensolver also now provide clients with comprehensive blade inspection reports in hard copy and via Cornis web portal. This bespoke analysis capitalizes on quality photographic imagery and the power of Cornis’ data processing and image enhancing core competency. They are also combined with Greensolver’s knowledge of site operations and safety requirements.

The result is a system that not only provides an almost immediate health statement on 100% of the blade surface, but also allows long-term blade condition monitoring, as the scheduled imagery can be readily compared over time within the web portal.

With almost immediate single-person mobilization, low health and safety risks are considerably reduced, as is turbine downtime (which is limited to just one hour), so the impact on turbine productivity is minimized. The reduction in the requirement for multi-person inspection teams and additional equipment results in lower overall costs, including the expenses associated with weather downtime, which can be significant with other technologies.

“In maintenance terms, wind turbine blades are often referred to as the new gearbox,” said Stephen Bolton, General Manager, Greensolver UK. “Ultimately what this means therefore is that when combined with the increased focus on driving down long-term operational costs and enhancing fleet performance, we need a suitable ISO55001 compatible, long-term inspection solution. Following an extensive market evaluation, we believe that with the Cornis Blade Inspection camera system we can achieve these combined goals and achieve significant budget savings simultaneously.”

Bolton added: “Based on our own experience of managing an extensive European fleet, traditional blade inspection services that include rope access, mobile elevated working platforms, ground scope, and the use of drones and helicopters are expensive, inefficient and arguably pose an unnecessary health and safety risk when used as the sole means of initial inspection. This, combined with the experience and feedback from our long-term retained client base, led us to a partnership with Cornis Blade Inspection.”

As part of the agreement between the two firms, Greensolver has leased and purchased the equipment and fully trained its team of engineers. Cornis will work directly with Greensolver to process the data and produce the reports.

Greensolver

http://greensolver.net

Filed Under: Blades, Insurance, News