The wind turbine technology Carter has developed is most significant in that it produces four times the energy per pound of equipment weight versus conventional wind turbine designs.

Carter Wind Energy is a manufacturer of next-generation wind turbine technology that is self-erecting and designed for utility, distributed, and micro-grid power generation applications in the most remote, extreme environment locations which may not be viable with conventional wind turbine technologies. Wind energy is more commercially available than ever but accounts for less than 5% of global energy production.

The challenge: For clean energy sources such as wind to gain mass adoption, it must become as cheap and available as traditional fossil fuels.

Over time, wind turbine size and project scale have steadily grown. This approach for reducing the cost of energy has limits, with rapidly decreasing benefits. The continued affordability of wind power is limited by existing wind turbine technologies with incremental improvements not being enough to make clean energy globally significant. It is time to rethink the traditional three-blade wind turbine architecture.

Carter Wind Energy has a solution. The wind turbine technology Carter has developed is most significant in that it produces four times the energy per pound of equipment weight versus conventional wind turbine designs. The capital investment required to manufacture, transport, install, and maintain wind turbines, is a function of equipment weight. More energy with less equipment weight means a lower cost of energy.

The dramatic reduction in the cost of energy afforded by the Carter wind turbine technology will create vast new market opportunities for wind energy and most importantly, allow for the economical global mass adaption of clean renewable energy.

Carter Wind Energy is selecting early adopting partners and customers, who are industry leaders, not satisfied with the status quo, who are interested in advancing the state of the art in the wind industry through support in the commercialization of a proven, significantly lower cost wind energy technology.

Investment in new promising technologies/products brings with it the hope of a future where wind power is cost competitive with conventional power generation without subsidy. After 25+ years, the wind industry must begin to demonstrate there is a future where the cost of energy from wind is competitive without subsidy.

The wind turbine technology Carter has developed is most significant in that produces four times the energy per pound of equipment weight versus conventional wind turbine designs. The capital investment required to manufacture, transport, install, and maintain wind turbines, is a function of equipment weight. More energy with less equipment weight means a lower cost of energy. GE, Vestas, Siemens, Enercon, and others all understand the critical importance reducing weight has in lowering the cost of energy.

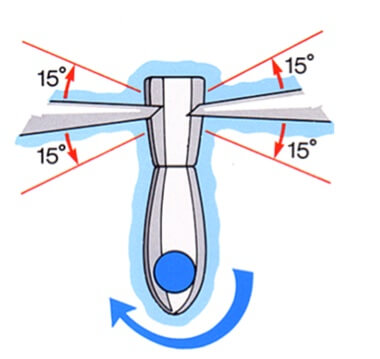

The Carter wind turbine design operates on the same principles as a conventional wind turbine but achieves its superior energy to weight advantage by successfully integrating the enabling technologies of the helicopter industry into our wind turbine design.

Carter’s competitive advantage lies in its proprietary:

- Two bladed, downwind, teetering, bearingless rotor hub design, which eliminates and reduces many of the loads encountered by three blade turbines;

- Self-erecting guyed tower concept which eliminates the need for large expensive cranes for installation and maintenance.

By minimizing loads and utilizing a structurally efficient guyed tower, Carter turbines weigh a fraction of three-bladed designs. The lighter weight and self-erecting tower result in a lower manufacturing, installation, and maintenance costs, and as a result, allows our turbine designs to achieve a dramatic reduction in the cost of wind-generated renewable energy.

As a result of the lower weight fraction, this technology’s optimal size for use in multi-MW onshore and offshore turbines will be larger than conventional 3-blade design, allowing for further reductions in cost. The result is a wind turbine architecture that can produce electricity at a cost that is competitive with the lowest cost fossil-fueled power plant without the need for subsidy.

Filed Under: Blades, Community wind