GE Renewable Energy has confirmed that the Haliade-X 12-MW nacelle and 107-meter-long blade will be shipped to the UK as part of an advanced technology testing program that will focus on enhancing the Haliade-X platform before it enters into serial production in 2021. The turbine’s nacelle will undergo a program that will replicate real-world operational…

GE ships tower sections for Haliade-X 12-MW prototype

GE Renewable Energy announced the shipment of the four tower sections that will be part of GE’s Haliade-X 12-MW prototype to be installed later this summer in Maasvlakte-Rotterdam (NL). The four segments at tower manufacturer GRI’s site in Seville, will be arriving in the Netherlands before the end of the month. Upon arrival in Rotterdam,…

Robowind developing robotic tools for turbine blade O&M

Robowind, LLC announced that it has worked with Professors Praveen Shankar and Mahdi Yoozbashizadeh from California State University to develop robots and robotic tools for wind-turbine blade maintenance. This includes installation of turbine blade performance enhancements and improvements. Robotic capabilities in development include inspection, cleaning, sanding, blade repair, painting, performance coatings, installation of vortex generators,…

Detecting ice on wind-turbine blades

The estimated market potential for wind farms in cold climates is more than 200 GW, according to Clir Renewables, a renewable energy AI software company. However, cold-weather climates present unique challenges to wind operators and O&M technicians. For example, icing events on wind-turbine blades may lead to increased loads and reduced aerodynamics, increasing the risk…

Siemens Gamesa reaches 1 GW of SG 4.5-145 turbines sold

Siemens Gamesa Renewable Energy has been awarded another order by EDF Renewables to supply 30 SG 4.5-145 and 36 SG 2.7-129 wind turbines for the 232-MW Milligan wind project, located in Milligan County, Nebraska. This project marks 1 GW of SG 4.5-145 wind turbines sold worldwide. The contract also includes a service and maintenance agreement…

WindCom adds rope access to its blade service line-up

WindCom continues to build its reputation for addressing a diverse range of blade service needs by adding a new access method to its lineup. Starting in June 2019, rope access repairs will allow WindCom to provide yet another cost-effective option for completing the most demanding blade services in the industry. “Rope services will bring…

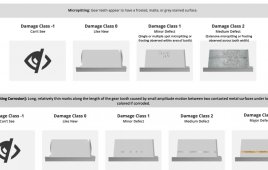

New standard accelerates digitalization efforts of wind industry

Often times digitalization is implemented within an organization without clear understanding of how digital tools can be used to address problems and generate business value. This is according to Sentient Science, which has developed a new damage classification standard for the wind industry. For example, the first wave of digitalization involved digitizing the standard SCADA…

PrecisionHawk’s AI & machine learning turns drone data into actionable intelligence

PrecisionHawk, Inc., a provider of drone technology for the enterprise, has announced PrecisionAnalytics Energy, a complete aerial mapping, modeling, and inspection platform that uses the latest generation of artificial intelligence and machine intelligence to automate analysis of their aerial data. PrecisionAnalytics’ customers can reduce costs up to 80% and dramatically improve safety in the field.…

LM Wind unveils 107-m turbine blade, currently the world’s largest

LM Wind Power is completing the final touches on what it says is the world’s largest wind-turbine blade at 107 meters. The blade is finished the molding process and will next receive post-molding finishing touches. The manufacturing is being done at LM Wind’s factory in Cherbourg, France. Lastly, the blade will undergo rigorous testing and…

ALLETE repowering two of its U.S. wind farms

ALLETE Clean Energy, a wholly owned subsidiary of ALLETE, has received the 45th set of new wind-turbine blades from international blade manufacturer Tecsis. The blades are for ALLETE’s refurbishment initiative at its Storm Lake and Lake Benton wind facilities in Iowa and Minnesota, respectively. In August 2017, the company announced an $80 million project that…

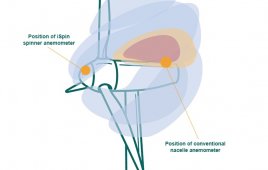

Romo Wind and eta Blades collaborate to extend lifecycle of aging turbines

Romo Wind’s iSpin technology monitors the performance and the wind site conditions for detailed load and lifetime assessments. eTa Blades re-designs and manufactures lighter and aerodynamically efficient blades for older turbine types. Together, the two companies are joining forces to provide an attractive refurbishment package for aging wind farms. “Based on eTa Blades deep understanding…

What’s new in wind-turbine blade manufacturing

Supersized. That’s an ideal description of what’s expected in the future of wind-turbine blades. They’re going to get big. What once extended the length of a basketball court will soon span the length of two (or more) American football fields. At least that’s what General Electric (GE) has been working on for wind. “It would…

ENGIE wind farm to feature first 150-m Vestas’ turbine blades

Vestas has received a 96-MW firm and unconditional order from ENGIE for the Eólica Tres Mesas IV project, located in Llera, Tamaulipas, Mexico. The order includes the supply and installation of 24 wind turbines of the 4-MW platform, as well as an Active Output Management 5000 (AOM 5000) service agreement for the operation and maintenance…

DNV GL issues landmark R&D study for supersized turbine blades

DNV GL has released an in-depth study, commissioned by the U.S. Department of Energy’s Lawrence Berkeley National Laboratory, which examines the challenges associated with manufacturing and deploying next-generation, increasingly larger land-based wind turbines. In the past decade, the U.S. wind energy industry has achieved significant improvements in energy production and cost efficiency, driven in part…

Meet EDDIE: An AI analytics engine from BladeEdge

BladeEdge, a provider of big data solutions for the wind industry, has launched “EDDIE,” or what the company says is the world’s first artificial intelligence (AI) image analysis engine designed specifically for the wind industry. EDDIE was created to enable automated condition assessments of blade inspection images, data analytic processing, and report generation. “EDDIE brings…

Joint Industry Project to tackle wind-turbine blade erosion

DNV GL, the world’s largest independent energy advisory and certification body, has launched a Joint Industry Project with ten commercial partners to develop a COmprehensive methodology for Blade Rain erosion Analysis, or COBRA. The COBRA Joint Industry Project has been set up to investigate the damage caused to leading-edge wind-turbine blades from the high-speed impacts of foreign objects, such as…

SWM launches Naltex flow media for resin-infusion processes

SWM International recently introduced Naltex flow media for resin-infusion processes to its host of offerings. This new flow media is engineered to retain up to 15% less wasted epoxy resin, which is commonly trapped in media grid apertures after processing — while maintaining high flow rates compared to current technology. Designed for wind energy resin…

Rope Partner and Power Curve to offer aerodynamic turbine performance upgrades

Rope Partner, a global rope-access maintenance, inspection, and performance enhancement service provider, announced the formation of a new partnership that will expand its offerings to the wind industry. The Santa Cruz based company has partnered with Power Curve to deliver aerodynamic performance upgrades, such as vortex generators. “This new partnership re-affirms our commitment to delivering the…

Nordex to produce wind-turbine blades in Mexico

The Nordex Group will soon produce all of its own rotor blades in Mexico. To this end, the company plans to set up a production facility in Matamoros, in the state of Tamaulipas. “With the plant in Matamoros, we are responding to the sharp rise in global demand for our products. In addition to the…

Erosion in wind-turbine blades solved with help of AI

The erosion of materials used in wind-turbine blades due to the effect of weather conditions is a problem that applies to the whole wind energy sector. VTT’s antiAGE project found a functional solution to the material problem with the help of artificial intelligence and 3D printing. The erosion of wind-turbine blade material is a surprisingly…