Global expenditure for wind turbines Operations and Maintenance (O&M) is expected to rise from $9.25 billion in 2014 to an estimated $17 billion by 2020, according to research and consulting firm GlobalData. The increasing number of installations and aging turbines are the primary cause for the predicted price hike.

A wind farm’s O&M is an essential price to pay—it contributes to value creation, increases turbine availability, and boosts returns, said Harshavardhan Reddy Nagatham, a GlobalData analyst.

O&M continues to change and improve as demand grows. In previous years, working up-tower on a wind turbine was challenging, if not impossible some times of year. “If a high-speed shaft or an intermediate bearing needed fixing inside a turbine, the gearbox had to come down,” explained Mike Grunow, Vice President of Sales and Marketing at Moventas. “Now we are able to do a lot of repairs up-tower.”

Replacing the gear on a high-speed shaft is now possible, but doing so depends on the turbine’s gearbox because the process calls for specialized tooling.

Common maintenance challenges that affect wind farms today include keeping gearbox oil clean and free of water contaminants. Specialists suggest using a harder surface of the gear to mitigate boundary lubrication.

“All manufacturers will use carburized gears in their gearboxes, but when it comes to the ring gear, many manufacturers choose other materials and hardening processes,” said Grunow. “As a result, the ring gear isn’t as durable in an environment with contamination. It builds up in the oil, and eventually the gearbox bearings will fail because of it.”

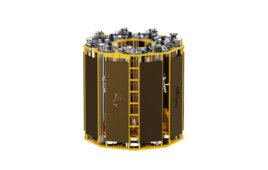

Size is another challenge for maintenance work in the wind industry. The bore of the planet wheel can only be so large before it loses rim thickness, and at a certain thinness the gear teeth will crack, said Grunow. Ultimately, bearing size is limited by size restrictions in the nacelle. An integrated bearing lets a manufacturer achieve greater capacity in the planetary stage of a gearbox.

Wind-farm owners are tracking and monitoring their assets to reduce turbine maintenance and increase performance whenever possible.

“Regular O&M reduces the downtime of a turbine and optimizes electricity generation, which leads to an increase in revenue,” said Nagatham. “In optimal conditions, O&M activity guarantees a turbine life of 20 years. Life may be further extended through improvements and adaptations during the later years of its lifecycle.”

Quality O&M services are designed to maximize gearbox life through the early detection of mechanical problems. Using more than simple vibration analysis, one program in the industry uses real-time multi-sensor monitoring of gearbox vibration, oil condition, and particle counts. This allows diagnosing some potential problems months in advance, Grunow said.

For aging and post-warranty wind turbines, a few programs may help reduce maintenance and repair costs. One in particular, offered by Moventas, gives customers a refurbished or brand-new replacement gearbox in exchange for their damaged gearbox. Customers only pay the cost of the repair, and they benefit from minimized downtime and crane usage, according to the company.

“Maintenance can be proactively planned, which limits downtime,” said Grunow.

Filed Under: Featured, News, O&M